Building

a Dedicated Bootloader Board

for New

ATmega328P Microcontrollers

(December

2012)

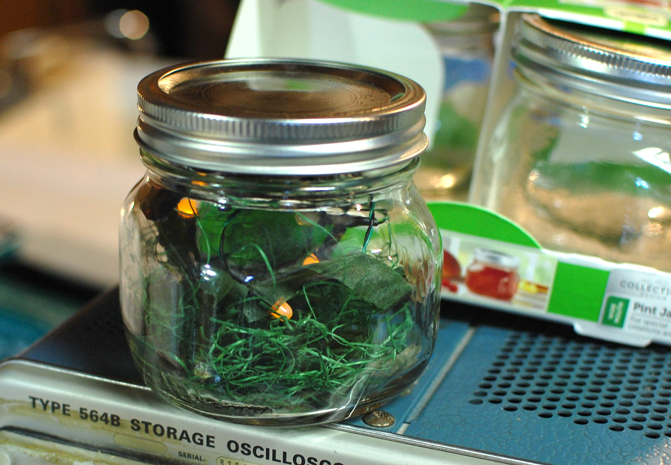

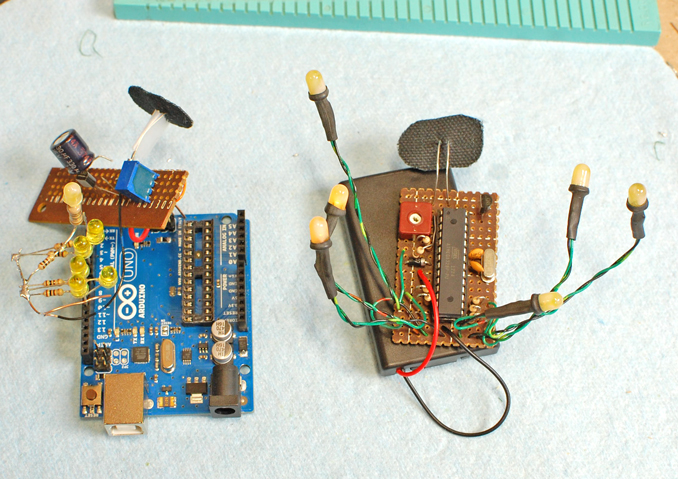

The very first thing that

I tried to do when I began my Digital Firefly Jar project was to burn bootloaders

to newly manufactured ATmega328P microcontrollers. I knew that to

reproduce my project I would need to make multiple programmed ATmega328's

and in anticipation of doing many Arduino projects I bought the chips in

bulk. I knew that I would have to burn bootloaders to all of them

in order to upload and use my sketches. I bought a used Arduino Duemilanove

to do this, and there was a clearly laid out tutorial

about burning bootloaders on a breadboard on the Arduino site.

It seemed like a no brainer - an easy task - but it wasn't... It

just did not work! Many attempts using the set up in the Arduino

tutorial met with no success, so I went to the blogs and saw that many

people were having problems doing this, and there were as many apparent

solutions as there were issues. I tried every configuration from

every blog I could find on the topic: adding pull up resistors, changing

power supply, altering settings, changing cables, etc.... but nothing

worked. The afternoon I spent trying every one of these configurations

to burn a bootloader met with nothing but errors.

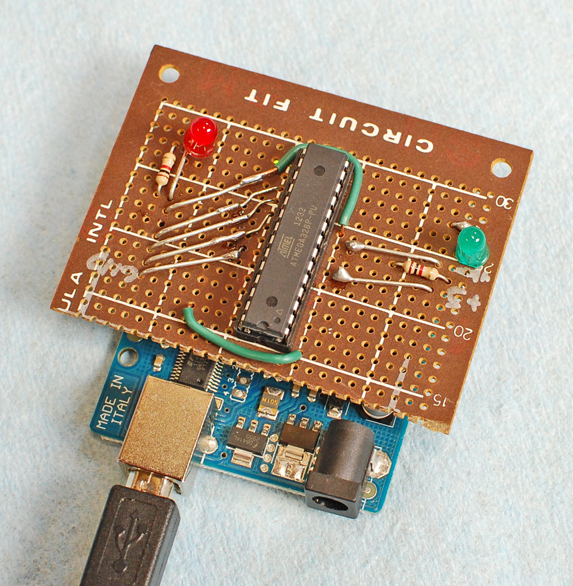

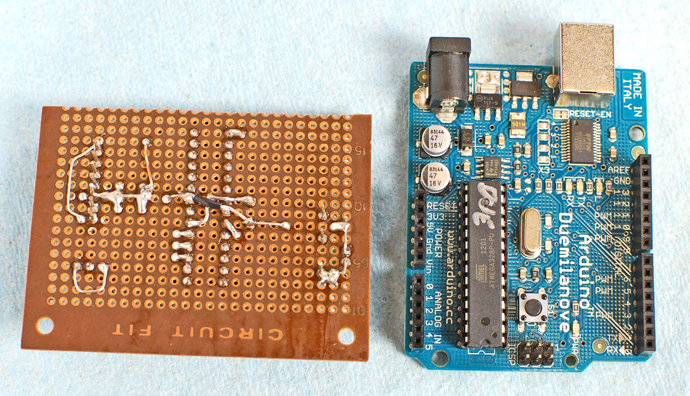

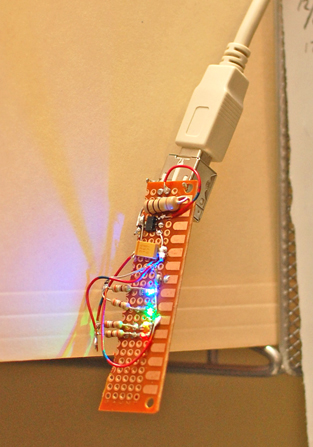

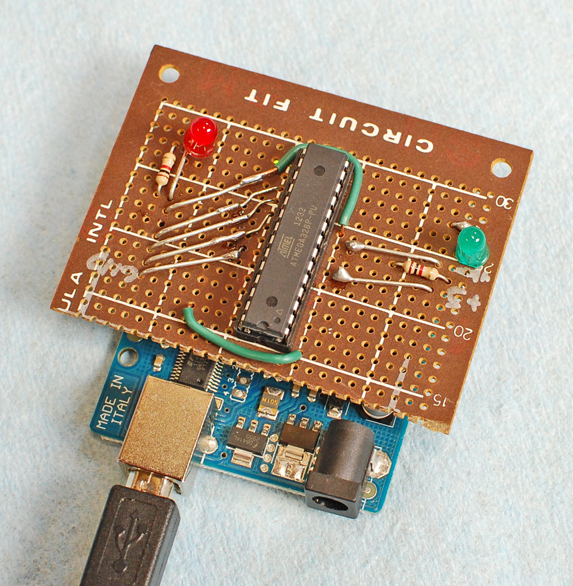

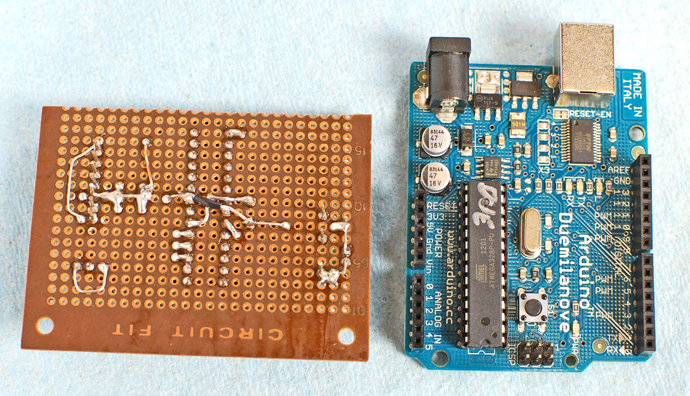

So I decided to go a different

route and tried the dedicated

bootloader board project suggested by Ladyada

that used a very nifty

Arduino sketch that had the Duemilanove's ATmega328 do the task, and

this elegant set up works flawlessly. Success! And a really

cool project too!